This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Textile recycling startup Circ inks new partnership to help it scale

MALIHA SHOAIB October 30, 2024

Indian conglomerate Aditya Birla Group has committed to buying up to 5,000 tonnes of Circ pulp per year over a five year period.

One of the biggest challenges material innovation startups face is moving their technology from pilot phase to commercial reality. It’s a chicken and egg situation — startups need suppliers to produce their materials at scale for brands to be able to use them, but brands are reluctant to commit to using them before they are available at scale.

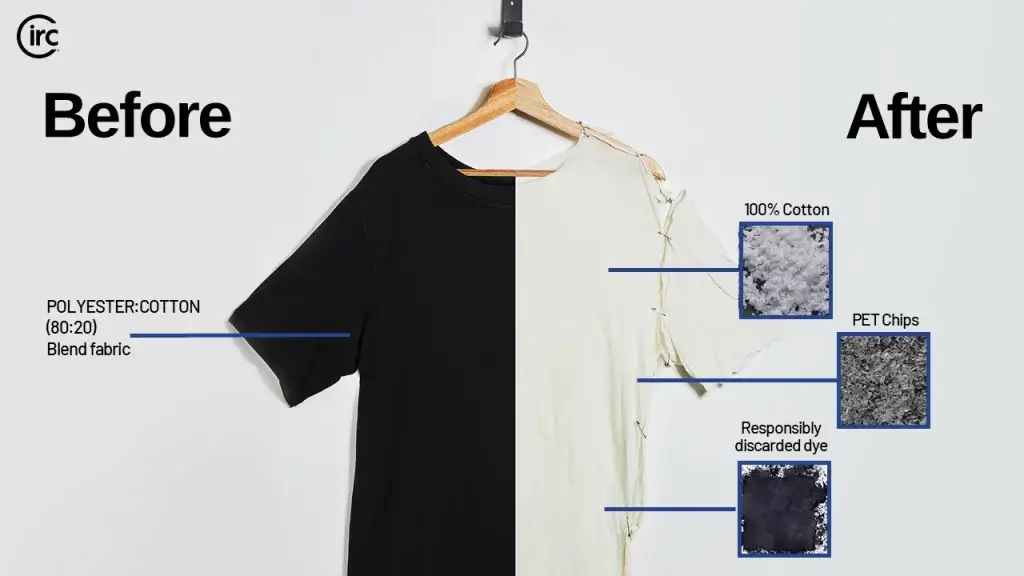

US textile recycling startup Circ is launching a supplier partnership that could help it break through the impasse. The company has signed a deal with Indian conglomerate Aditya Birla Group’s pulp and fibre production arm, Birla Cellulose, which will purchase up to 5,000 metric tonnes of pulp per year over a five year period from Circ’s first-ever commercial-scale facility. Birla Cellulose will convert Circ’s pulp into lyocell staple fibre, which brands can use to create clothes. (Some brands, including Zara, have already begun producing garments with Circ, but so far, recycled fibres represent a drop in the ocean.)

“Supplier involvement is an essential piece in making circularity a reality at scale. By engaging a major supplier like Birla, we’re able to demonstrate demand for recycled inputs while building a robust, scalable infrastructure,” says Circ co-founder and CEO Peter Majeranowski. Circ says that clothes made from its lyocell can eventually be recycled back into Circ pulp.

The announcement comes at a significant moment for fashion, months after fellow recycling startup Renewcell (now known as Circulose, under a new owner) shook the industry when it declared bankruptcyearlier this year. Renewcell had begun to seem like the first realistic contender to deliver textile recycling at scale. When it declared bankruptcy, startups — as well as suppliers and brands — braced for a pause in the momentum that had been building around next-gen materials.

The partnership between Circ and Aditya Birla could inject fresh energy into fashion’s efforts to pursue and scale material innovation.

“This partnership reflects our commitment to environmental stewardship and represents a crucial step in advancing innovation within the textile industry,” says Aspi Patel, Chief Technology Officer at Grasim Industries Limited, one of Aditya Birla Group’s flagship companies. Birla Cellulose has 12 manufacturing sites for man-made cellulosic fibres dedicated to using closed-loop technologies and recycled materials. “By integrating Circ’s cutting-edge recycling technology with our cellulosic fibres, we are enhancing the potential for a truly circular economy,” adds Patel.

Birla Cellulose’s size is key for Circ to prove — to the industry at large, but to brands and investors in particular — that it’s on a viable path to true industrialisation.

“This momentum is what will enable brands to make bolder commitments [and] suppliers to accelerate their transformation,” says Majeranowski. “With suppliers like Birla committing to the circular economy, it’s clear that we’re no longer talking about distant sustainability goals. We’re building the reality, right here, right now.”